Below shows the hookup of the EasyDriver Stepper Motor board I used to control the stepper motor used in my fish feeder. This wiring is well documented on Sparkfun. Again, this board can be purchased from many stores domestic and overseas.

The video below shows a test run of the stepper motor doing a 360-degree turn. If you are not familiar with the difference between a regular motor and a stepper motor, with a stepper motor you can control the motion of the motor in discrete steps, vs a regular motor which when power is applied just runs until power is removed. This type of action is convenient when building a fish feeder because you can control the motion used to drop food exactly.

I mounted the motor in the hood of my aquarium using wood and some removable plastic pieces that allow it to be firmly held in place and removed as needed.

I then connected the stepper motor shaft to a rod that was inserted through a round plastic container. The rod was run from the bottom of the container to the top (i.e. through the lid). Silicone was used where the rod went through the bottom of the container to essentially glue the two pieces together. The motor then rotates the container through the center smoothly and with minimal effort. The other end of the rod rests in a hole in the side of the wooden hood. I inserted a small sleeve bearing in the wood for the rod to sit in so there was minimal friction.

I then connected the stepper motor shaft to a rod that was inserted through a round plastic container. The rod was run from the bottom of the container to the top (i.e. through the lid). Silicone was used where the rod went through the bottom of the container to essentially glue the two pieces together. The motor then rotates the container through the center smoothly and with minimal effort. The other end of the rod rests in a hole in the side of the wooden hood. I inserted a small sleeve bearing in the wood for the rod to sit in so there was minimal friction.

The following video shows the feeder in action and how food exits through a small PVC pipe:

As you can see in the video I cut a hole in the side of the plastic container and took a piece of PVC acting as a scoop on one side and means of exit from the container on the other. This PVC was also sealed with silicone where it exits the container.

The scoop side of the PVC, where I cut a small notch, is particularly sensitive to how much food is picked up. I used some tape on the notch to adjust how big it was, as it takes a bit of tuning to get the right amount of food to drop. You may be able to cut the notch in the PVC exactly right to get just a small amount of food to drop, but a simple adjustment is to partially cover the notch.

The scoop side of the PVC, where I cut a small notch, is particularly sensitive to how much food is picked up. I used some tape on the notch to adjust how big it was, as it takes a bit of tuning to get the right amount of food to drop. You may be able to cut the notch in the PVC exactly right to get just a small amount of food to drop, but a simple adjustment is to partially cover the notch.

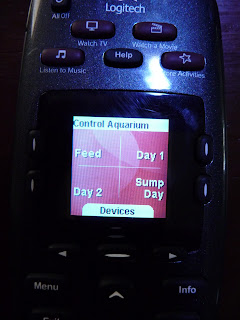

Below shows how I took a Logitech universal remote and programmed some labels for the aquarium to have a feed function. This looks complicated, but it's a pretty easy addition to any Arduino project which you can read about on Ken Shirriff's blog. You'll see that the blog describes receiving a Sony TV remote signal, so if you use a universal remote you just need to configure it to send a Sony TV signal (e.g. channel up, down, 1, 2, etc.) and map the buttons to the action you desire in code. The remote does not need to be as fancy as this Logitech remote. I also did something similar for my Arduino Chicken Coop.